roll conveyor and support conveyor for coal crusher

Conveyor & Crushing | Mill Creek Engineering

Ash Handling. Millcreek provided detailed design of a covered two-segment overland conveyor system used to transport 3 million tpy of coal combustion residuals over 7,400 linear feet at 1400 tph from the power plant to the landfill. Feeders, stacking equipment, and transfer points were strategically placed to minimize material handling.

Read More

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

2015-4-10 · coal on either sides of the yard conveyor. During stacking mode coal is fed from conveyors on boom conveyor and while in reclaim mode, boom conveyor discharges coal on the yard conveyor for feeding coal to bunkers through conveyors and transfer points. The yard conveyor can be reversible type depending on layout requirement. Figure 2: Coal ...

Read More

Bulk Material Belt Conveyor Specification

2012-12-30 · 5.1.2 Coal or limestone will be dumped into the below grade reclaim hopper (hopper and pit structure by others) by the owner's front loader, as shown on drawing AAH-G01-002E. A belt feeder (by others) will transfer the coal or limestone to the roll type crusher (by others). The crusher will discharge into the

Read More

Roller / Industrial Conveyor Belt System | Belt Conveyor ...

Industrial belt Conveyor Parts : 1. Conveyor Belt. The belt conveyor is an endless belt moving over two end pulleys at fixed positions and used for transporting

Read More

Design and Analysis of Belt Conveyor Roller Shaft

2017-2-8 · ears. Belt conveyor is one of the main transport equipment in coal mine, driving drum and belt is its key part. Friction principle is used to initiate mechanical drive for belt conveyor. So friction is the driving force. In order to raise transportation efficiency of belt conveyor, driving force of drum must be increased.

Read More

Roll Crusher - an overview | ScienceDirect Topics

Roll Crusher. For a given reduction ratio, single-roll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal. Double-roll crushers consist of

Read More

Construction and Maintenance of Belt Conveyors for

2018-4-27 · 6 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants practicalmaintenance.net also oscillating horizontally. This phenomenon results in internal agitation to the material on belt and therefore the material’s external faces assume inclination at surcharge angle.

Read More

DESIGN OF MATERIAL HANDLING EQUIPMENT: BELT

2015-4-15 · C = Capacity in tones/hr of a belt conveyor consisting of 3 equal roll idler; c T = Capacity of troughed belts for 3 roll equal length idler (175); = material density in kg/m3 (1000); c f = Capacity factor (1.08); and V = Belt speed in m/s (1.25) From Equation (2.4), the overall capacity of the belt conveyor consisting of 3 equal roll idler is ...

Read More

Belt Conveyors for Bulk Materials - Fifth Edition - Chapter 6

2018-11-14 · The frictional resistance of idler rolls to rotation and sliding resistance between the belt and the idler rolls can be calculated by using the multiplying factor K x . K x is a force in lbs/ft of conveyor length to rotate the idler rolls, carrying and return, and to cover the sliding resistance of the belt on the idler rolls. The K x value ...

Read More

Mobile Hopper Belt Conveyor For Coal

mobile coal conveyors. Mobile Coal Conveyor For Sale In Usa cheap mobile stacking conveyor china rock crusher and mine used radial stacking conveyors in oklahoma Get Price And Support Online mobile coal conveyor gyrf Mobile coal conveyor for sale in USA Quartz Solutions study on technical and economic feasibility of mobile bucket elevators for ...

Read More

CRUZER Double roll coal crusher

2013-4-11 · CRUZER Double roll coal crusher. Most reliable coal crusher in Indonesia market today. Low operational cost with high gain of productivity. GREATBELT - Conveyor belt. ... This CPP using of our 500 Tph double roll coal crusher combined with our other conveyor part.

Read More

Horizontal Impact Crusher | HHI - HAZEMAG

The HAZEMAG HHI Horizontal Impact Crusher comprises two machine components: the crushing roll and the chain conveyor. The arrangement of the crushing roll above the horizontal chain conveyor permits the conveyor to be utilised as both feed conveyor and discharge conveyor. This system for crushing has achieved proven success in numerous ...

Read More

Pipe conveyors for coal transportation at Ledvice -

2022-2-6 · Pipe conveyors for coal transportation We supplied pipe conveyors for coal transportation in two phases. Phase 1 is a double line pipe conveyor that transports coal from the new coal crusher station to the existing boilers B1-B4.

Read More

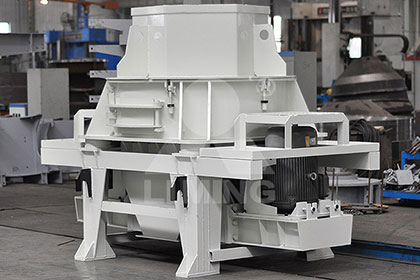

Roll Crusher – LITech GmbH

Roll Crusher. The LITech Roll crusher is used to pre-crush hard, medium-hard, hard-tough, brittle and soft materials. Roll crushers RC 100 / 200 / 300 are essential for contract laboratories, industry and universities where hard, brittle, hard-tough and soft materials need to be prepared for the following analaysis.

Read More

Bulk Material Belt Conveyor Specification

2012-12-30 · 5.1.2 Coal or limestone will be dumped into the below grade reclaim hopper (hopper and pit structure by others) by the owner's front loader, as shown on drawing AAH-G01-002E. A belt feeder (by others) will transfer the coal or limestone to the roll type crusher (by others). The crusher will discharge into the

Read More

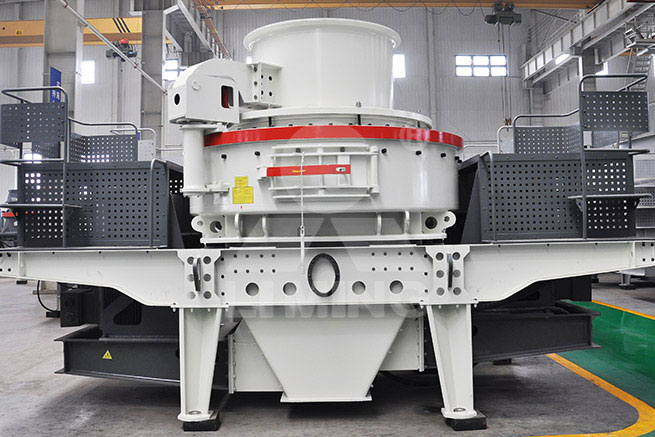

Coal Double Roll Crusher VS Coal Single Roll Crusher

Coal double roll crusher: raw materials, secondary raw materials and by-products such as clean coal, coal with rock; Coal Single roll crusher is used for grain size reduction for products ranging from soft to medium-hard; Mode Of Operation. The double roll crushers are individually driven in counter rotation by ample drive arrangements.

Read More

Construction and Maintenance of Belt Conveyors for

2018-4-27 · 6 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants practicalmaintenance.net also oscillating horizontally. This phenomenon results in internal agitation to the material on belt and therefore the material’s external faces assume inclination at surcharge angle.

Read More

Belt Conveyors for Bulk Materials - Fifth Edition - Chapter 6

2018-11-14 · The frictional resistance of idler rolls to rotation and sliding resistance between the belt and the idler rolls can be calculated by using the multiplying factor K x . K x is a force in lbs/ft of conveyor length to rotate the idler rolls, carrying and return, and to cover the sliding resistance of the belt on the idler rolls. The K x value ...

Read More

DESIGN OF MATERIAL HANDLING EQUIPMENT: BELT

2015-4-15 · C = Capacity in tones/hr of a belt conveyor consisting of 3 equal roll idler; c T = Capacity of troughed belts for 3 roll equal length idler (175); = material density in kg/m3 (1000); c f = Capacity factor (1.08); and V = Belt speed in m/s (1.25) From Equation (2.4), the overall capacity of the belt conveyor consisting of 3 equal roll idler is ...

Read More

Roller / Industrial Conveyor Belt System | Belt Conveyor ...

Industrial belt Conveyor Parts : 1. Conveyor Belt. The belt conveyor is an endless belt moving over two end pulleys at fixed positions and used for transporting material horizontally or at an inclined up. 2. Conveyor Pulley. Following types of conveyor pulleys are used in

Read More

Get Reliable High-Quality Durable crusher conveyor belt ...

These crusher conveyor belt are tailor made according to the technical demands of the working environment. The quality crusher conveyor belt do not shrink at high temperature. These industrial crusher conveyor belt are economically friendly. They are available at affordable competitive prices and thus prove to be economically efficient.

Read More

Pipe conveyors for coal transportation at Ledvice -

2022-2-6 · Pipe conveyors for coal transportation We supplied pipe conveyors for coal transportation in two phases. Phase 1 is a double line pipe conveyor that transports coal from the new coal crusher station to the existing boilers B1-B4.

Read More

Conveyor & Crushing | Mill Creek Engineering

Ash Handling. Millcreek provided detailed design of a covered two-segment overland conveyor system used to transport 3 million tpy of coal combustion residuals over 7,400 linear feet at 1400 tph from the power plant to the landfill. Feeders, stacking equipment, and transfer points were strategically placed to minimize material handling.

Read More

Roll Crusher – LITech GmbH

Roll Crusher. The LITech Roll crusher is used to pre-crush hard, medium-hard, hard-tough, brittle and soft materials. Roll crushers RC 100 / 200 / 300 are essential for contract laboratories, industry and universities where hard, brittle, hard-tough and soft materials need to be prepared for the following analaysis.

Read More

Spy Group Holdings... Crushing, Screening, Conveyor Idlers ...

2021-3-9 · Some of these are jaw and double roll crushers, screens, front-end loaders, forklifts, water tanks, power generators, excavators, conveyor idlers and rolls. Coal Processing Our mobile crushing and screening systems are designed in ways that reduce the re-processing the coal after primary crushing has occurred and is in-line with the current ...

Read More

Construction and Maintenance of Belt Conveyors for

2018-4-27 · 6 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants practicalmaintenance.net also oscillating horizontally. This phenomenon results in internal agitation to the material on belt and therefore the material’s external faces assume inclination at surcharge angle.

Read More

Coal Screening - Roller Screens | Coal Handling Plant

Roller Screens are suitable for separating fine, coarse and sticky coal. They are used in coal handling plant for preliminary screening and relief to crusher as well to ensure a clog free flow of coal. Roller Screens Consist Of Following Parts 1. Drive Unit. The screen is driven by electric motor through gear box.

Read More

Conveyor Roller, Idler roller, Carrying Roller, Impact ...

2022-2-9 · Carrying rollers are used to support the conveyor belt and are installed on the groove shape frame, Groove shape forward inclined idler frame and transition idler frames. Rollers include high quality bearing, multi-labyrinth sealing, greased and sealed for life and critical specifications essential for high performance.

Read More

Belt Conveyors for Bulk Materials - Fifth Edition - Chapter 6

2018-11-14 · The frictional resistance of idler rolls to rotation and sliding resistance between the belt and the idler rolls can be calculated by using the multiplying factor K x . K x is a force in lbs/ft of conveyor length to rotate the idler rolls, carrying and return, and to cover the sliding resistance of the belt on the idler rolls. The K x value ...

Read More

DESIGN OF MATERIAL HANDLING EQUIPMENT: BELT

2015-4-15 · C = Capacity in tones/hr of a belt conveyor consisting of 3 equal roll idler; c T = Capacity of troughed belts for 3 roll equal length idler (175); = material density in kg/m3 (1000); c f = Capacity factor (1.08); and V = Belt speed in m/s (1.25) From Equation (2.4), the overall capacity of the belt conveyor consisting of 3 equal roll idler is ...

Read More

- << Previous:China Clay Small Grinding Machine In India

- >> Next:Grinding Plant Indonesia