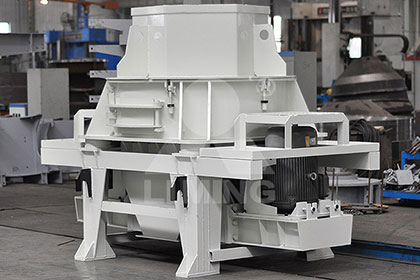

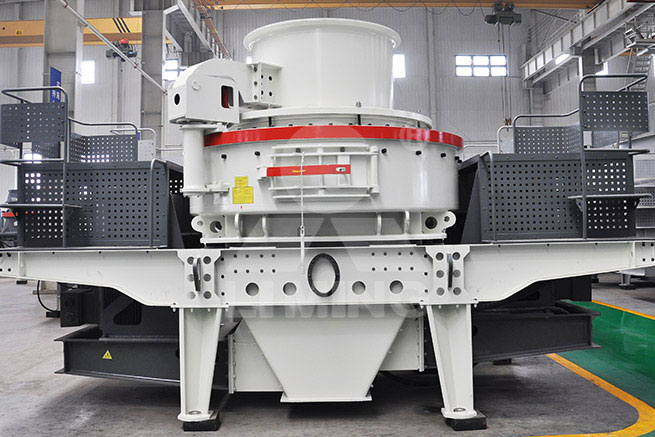

VSI5X Impact Crusher

Product Introduction

VSI5X series of efficient centrifugal impact crusher, introducing the advanced German technology, is the new generation products owning many patents. Center feeding & ring feeding: The materials fall into the hopper and the circle hole and then will be divided into two parts by the distributing plate. One part of materials cross the distributing plate and ent...

Product Usage

Mechanism sand, bituminous concrete, metal mine, aggregates shaping

Product advantages

1.After optimized design, the deep-chamber rotor can make the capacity increased by 30%.

2.Surrounding plate is revertible, to improve the material’ s utilization and increase more than 48% of the lifespan.

3.Combined hammer design, only need to replace the wearing part, can reduce the operation cost by over 30%. And the use of vice hammer can prevent damage to the vertical plate after the main hammer worn.

4.The key components’ materials adopt the wear-resistant and high temperature resistant materials of the important industries in the USA.

5.Rhombus shape impact plate is used to prevent the damage of vertical plate.

6.The selection of bearing is international brand from Japan, Sweden, America, etc.

7.The design of optimal launch mouth and smooth curve reduces flow resistance of the materials and increases the through out capacity greatly.

8.Dual-use material distribution tray is easy to operate and can make two feeding way changes easily.

9.Special seal structure in lower part of main shaft guarantees no oil leak even without seal.

10.Japanese hydraulic opening cover device is originally imported. The cover is moved easily and replacement and inspection of inner part is easy.

11.The selection of high level protection of the motor with features of high efficiency, low noise, etc. The motor complies with (IEC) International Electro technical Commission standard, F class insulation, IP54/55 protection level.

working principle

Center feeding: Materials fall into the hopper and then through the feeding open in the center enter the high speed rotor which will throw out the materials with high speed. Materials firstly strike those materials that are free falling down. Then, materials strike the materials-liner in the vortex or the impact liner and are rebounded to the top of crushing chamber and then fall down. After that, the falling materials with materials shot from the impeller form a continuous materials curtain. Ultimately, crushed materials will be charged from the discharging open.

Center feeding & ring feeding: The materials fall into the hopper and the circle hole and then will be divided into two parts by the distributing plate. One part of materials cross the distributing plate and enter the high speed impeller and then is accelerated and thrown out. The other part falls down from the sides of distributor. Materials firstly strike the free falling down materials. Then, materials strike the materials-liner in the vortex or the impact liner and are rebounded to the top of crushing cavity and then fall down. The falling materials with materials shot from the impeller form a continuous curtain of materials. At last, crushed materials will be discharged from the discharging opening.

Technical Parameters

1. Main technical parameters:

| Model | VSI5X7615 | VSI5X8522 | VSI5X9532 | VSI5X1145 | |

| Throughput capacity (t/h) | Center and Ring feeding | 150~280 | 240~380 | 350~540 | 500~640 |

| Center feeding | 70~140 | 120~190 | 180~280 | 250~360 | |

| Max. Feed Size (mm) | Soft material | <35 | <40 | <45 | <50 |

| Hard material | <30 | <35 | <40 | <45 | |

| Rotation speed (r/min) | 1700~1900 | 1500~1700 | 1300~1510 | 1100~1310 | |

| Power of double motor (KW) | 2×75 (100) | 2×110 (150) | 2×160 (220) | 2×220 (300) | |

| Overall dimension L×W×H (mm) | 4100×2330×2300 | 4140×2500×2700 | 4560×2600×2900 | 5000×2790×3320 | |

| Weight (t) | 8.6 | 11.8 | 17.5 | 27.5 | |

| Thin oil lubrication station | Power for double oil pump | 2×0.25(0.33) | |||

| Safety | TO make sure the supply of the oil with double oil pump; stop working without oil or hydraulic pressure; temperature falls when the water cool;start the motor by heating it in winter | ||||

| Power for oil box heater | 2 KW | ||||

| Overall dimension L×W×H (mm) | 820×520×1270 | ||||

Note: Capacity depends on crushing limestone, material size, moisture and features also affect capacity.

2. Lubricating system parameter:

| Oil box volume (L) | 240 |

| Rated pressure (MPa) | 0.63 |

| Flow capacity (L/min) | 8 |

| Power (KW) | 0.31 |

| Cooling water consumption (m3/h) | ≥1.2 |

| Electrical heating voltage (V) | 220 |

| Medium | Bearing oil 32—46# |